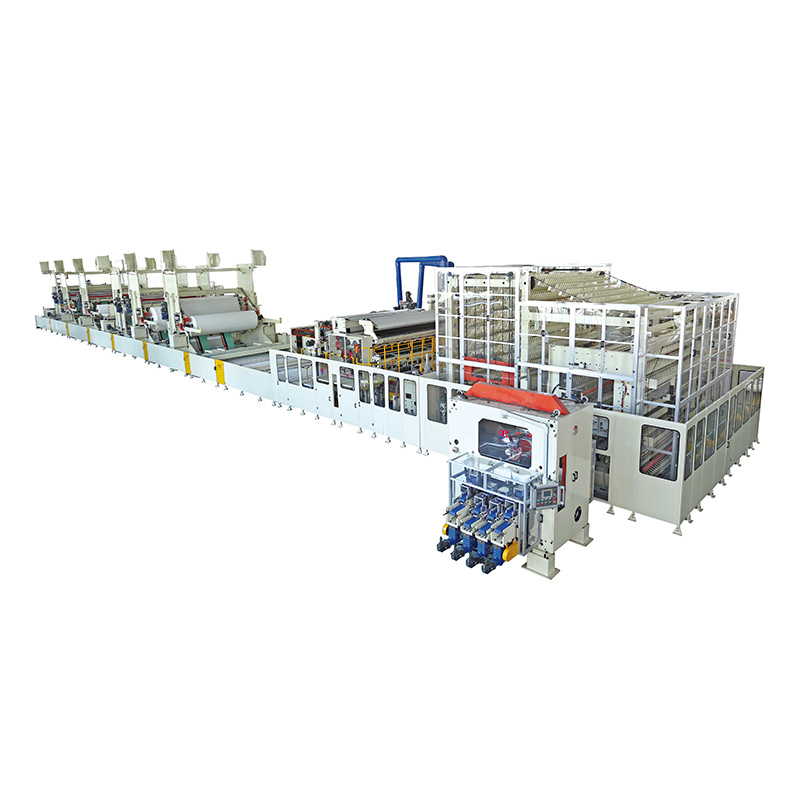

OK-100FJ-PJZ Double lanes Wallet Tissue Automatic Production Line

Technical Parameter

|

1 |

The finished Products: |

Wallet Tissue |

|

2 |

paper gsm: |

12-18g/㎡ |

|

3 |

paper ply: |

2、3、4ply |

|

4 |

Designing Speed: |

2000 sheets/min or 150 packs/min |

|

5 |

Production Speed: |

1500 sheets/min or 120 packs/min (1/6 folding) |

|

6 |

unwinder qty: |

2,use 1 and spare 1(use rotating tower) |

|

7 |

unwinder raw paper width: |

370-420mm |

|

8 |

raw paper diameter: |

Maxi.Φ1600mm |

|

9 |

raw paper core diameter: |

Φ76mm |

|

10 |

paper width: cutting length: |

185-210mm(cutting length is optional, customer can specify it) |

|

11 |

main machine power: |

20KW |

|

12 |

Compressed air pressure: |

≥0.6Mpa |

|

13 |

machine outline dimension: |

16249*1631(mm) |

|

14 |

vacuum pump power: |

22KW |

|

15 |

Packing Capacity: package thickness: |

Pillow Packing: 120 packs/min,6-12 sheets/pack 8-20μm |

|

16 |

packing material: thickness: diameter: inner diameter: |

Single wrapper: CPP+PE laminated film 40-70 μm maximumØ350mm 76mm |

Equipment description:

1. The equipment adopts a straight-line structure layout, continuous folding and packaging, beautiful appearance, smooth packaging, solid and reliable structure, the folding unit adopts the main motor belt drive, the packaging machine adopts full servo independent drive, high control accuracy, simple and convenient operation;

2. Raw paper unwinder constant tension control; paper calendering speed stepless speed regulation matching;

3. Adopt BST/Maxcess raw paper for automatic lateral deviation correction;

4. Programmable controller centralized control, touch screen operation, fault display and alarm, automatic shutdown protection, data statistics and other functions;

5.The paper size and number of sheets per pack can be customized according to customer needs, such as paper size: 200mm×200mm, 210×210mm...; number of sheets per pack: 6,8,10,12 sheets can be selected...;

6.Other optional function: point to point / point to flat / concave and convex roller embossing.