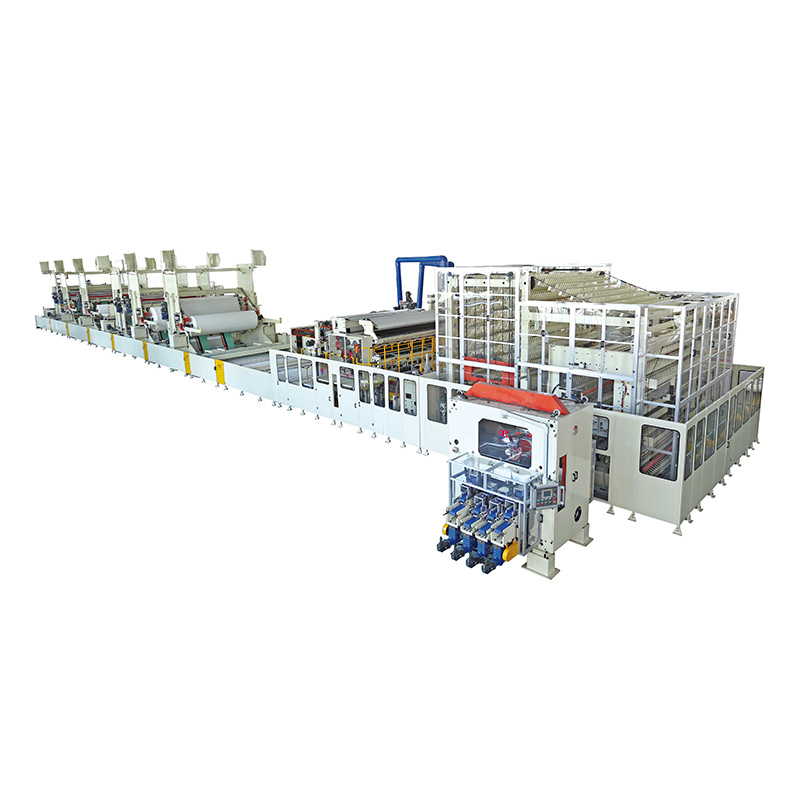

lotion Coating Machine

Main Technical Parameter

| item | Technical Parameter |

| Maximum width of Raw paper | 2850mm |

| Coating Working Speed | 100-150meters/min |

| Coating ingredient content | Main machine speed and mesh roller speed will effect lotion ingredient content |

| System Structure | Independent unit, in the form of integral wall board, equipped with horizontal adjustment device |

| Lotion Coating device | It is composed of 2 mesh rollers, 2 lotion transfer rubber roller, 2 paper pressing roller and 2 sets of lotion scraper system |

| Transmission device | Main drive: 11kW independent variable frequency motor drive, synchronous belt drive; motor, frequency converter, bearings, etc. Are all well-known brands at home and abroad(subject to the actual configuration) |

| Paper web wrinkle eliminating device | The inlet is equipped with a rotating arc-shaped rubber roller |

| Connection Mode | Coating unit is placed between the raw paper unwinder and rewinder machine, equipped with an independent operating panel and an electrical control cabinet. The lotion coating unit can be turned on or off according to product requirements. |

| Main power supply | Three-phase four-wire system, the control power supply is DC 24V |

| Total power | 35Kw(subject to the actual configuration) |

| Minimum air pressure requirement | 0.6Mpa |

| Air consumption | 10L/min |

Write your message here and send it to us